The DELTAFLOW, Model DF180, is a state of the art differential pressure measurement system used to calculate gas velocity and pollutant mass emissions in square, rectangular or circular air ducts and stacks using either single or multi point measurements. It especially excels in gas streams with challenging properties such as high temperature, moisture content, pressure, and corrosivity.

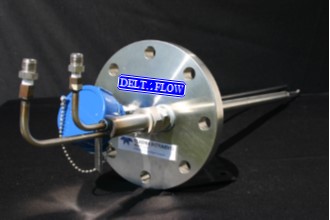

Pitot Tube Probe

Depending on the application, the pitot tube probe is constructed of stainless steel or hastelloy for easy cleaning and a long service life. A thermocouple temperature sensor is included in the probe assembly. The differential pressure measurement is performed using a pitot tube that is connected to a pressure sensor with Teflon tubing. Mounting is done by 4" flange; the tube is provided with an external indicator, so that its impact port can be accurately rotated to face directly into the gas flow.

Instrument Enclosure

The optional instrument box enclosure is rated NEMA 4/IP66 as standard equipment but can be upgraded with purge protection to meet Class 1, Division 2, Zone 2 specifications; it can be mounted at the stack/duct , climate controlled shelter, or at grade level. Pressure and temperature transducers and a custom valve and manifold design are housed within the enclosure; these components provide precision calibrations and blowbacks to maintain reliable accuracy.

Communications

The DELTAFLOW, Model DF180, Instrument Control Panel features 10/100 Based Ethernet interface as standard equipment. This capability provides a multilevel password protected interface to TCP/IP networks such as LAN's or the Internet. Client side user interface access is via standard web browsers. Simultaneous Modbus TCP access to instrument parameters and emission data is also supported.

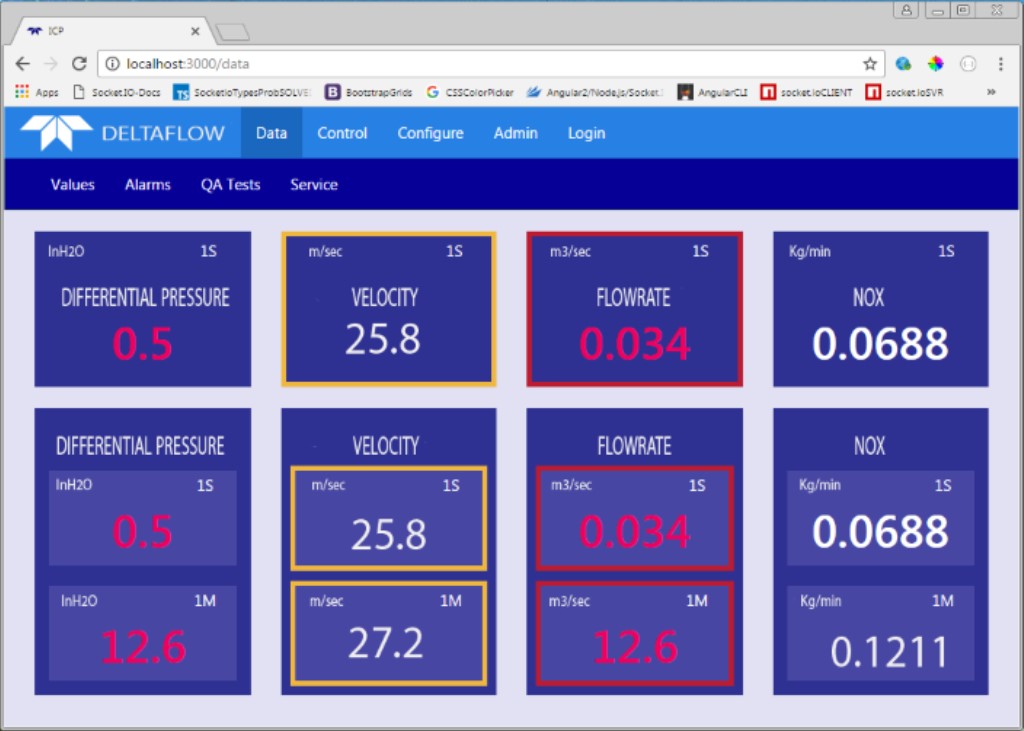

Web Browser Interface

The DELTAFLOW Ethernet web browser interface is used to view data, calibrations, alarms, configure, etc...